hp 85 gummy wheel cont...

| here's where the fun really starts.

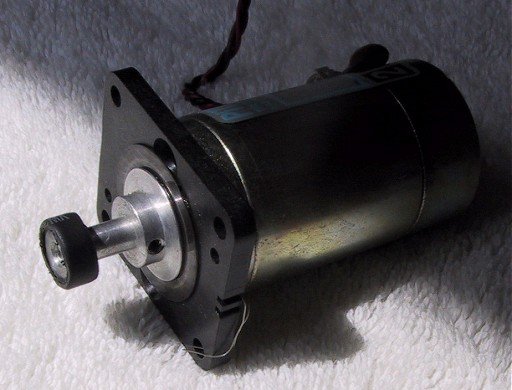

the capstan head is 3/8" diameter without the covering. i used 10mm heat shrink. even more fun is that i dont have a heat gun, but i do have a gas stove! if you have a heat gun then you can do this properly, but otherwise you can try my bodge. using a spare plastic insert from a cd you can push the capstan head through so that its fixed in (i put some paper tape on the back to hold it even better). the idea of the cd insert is to shield the optical base of the head and allow me to hold it near(ish) the flame. cut a small section of shrink, push it over the head then waft it near the heat, turning it around to get even heat all around. do not go too near the flame nor hold it close to the heat for any significant time, you only want to trigger the shrinkage and not melt the plastic! |

|

| using a very sharp knife trim off any excess at the

top.

i am not sure what the original rubber thickness was, so i put two coats of shrink (after that i couldn't get anymore of the 10mm shrink over the end). |

|

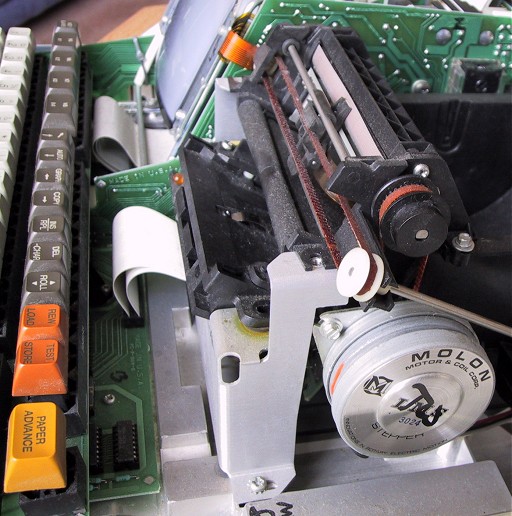

| reassemble the head onto the spindle. tighten the grub

scews.

the rest of the reassembly is exactly the reverse of dissasembly. fix the motor back to the board, plug it back in, carefully poke the two hair wires into their holes. push the two edge connectors back into the motor drive circuit board and then fix the board back onto the meta plate and fit on the earth connector (its much easier to connect the board before re-fixing the meta plate).

|

|

| carefully replace the tape unit back into the machine.

align the top printer screws and the base plate before tightening

completely.

|

|